After witnessing three major industrial revolutions, the world is at the forefront of the fourth revolution. Industry 4.0 is causing a distortion in the manufacturing industry, and the Internet of Things is entering the workshop. Machine-to-machine communication changes factories through decentralized control, and sensors guide factory workflows through smart devices; industrial assistant systems that use augmented reality and intelligent communications are helping manufacturers increase productivity, and social media is leading new forms of collaboration. Industry 4.0 represents a paradigm shift from centralized production to decentralized production; industrial production machinery no longer only processes products, but products now have the ability to communicate with machines and provide instructions.

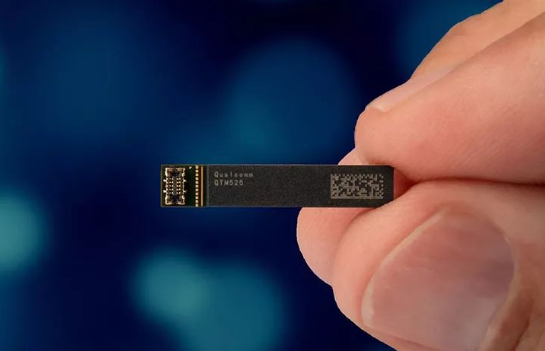

As the next stage of manufacturing modernization, Work 4.0 is driven by four levers: a significant increase in data volume and computing power; the emergence of support technologies such as big data and business intelligence; and new human-computer interactions such as touch interfaces and augmented reality systems. Improve the interaction between the real world and the virtual world, such as advanced robotics and artificial intelligence.

Although the Internet of Things has been around for a while, manufacturers have not accepted this concept on a large scale, which has led to a loss of process efficiency. Today's higher reliability and lower cost benefits are beginning to make sense for industrial applications. Industry 4.0 provides advanced tools for smarter energy management, greater process efficiency, greater information storage and real-time production optimization.

So what does Industry 4.0 bring? In the current manufacturing environment, producing high-end quality products at low cost is a mantra. Through this strategy, the goal is to achieve high performance output to increase profit and reputation. By using the data, you can better understand the current operating conditions. Using commercial tools, you can also highlight the root cause of the problem and possible failures in the system.

On the other hand, in the Industry 4.0 plant, in addition to monitoring and troubleshooting, self-aware and intuitive machines are used to gain a deeper understanding of the state of the production environment. Point-to-point communication and data integration from various components provide critical information about the health of the machine, triggering alerts for maintenance activities, ensuring near zero downtime, and ultimately resulting in higher throughput.

As the Internet of Things sweeps through manufacturing, smart production is rapidly evolving. Intelligent systems and networks capable of exchanging and responding to information are increasingly being used in the workshop to manage industrial production processes. The convergence of virtual and physical systems drives the development of smart factory concepts, which are characterized by significant savings in quality, time, resources and costs in addition to increased resiliency, fault tolerance and risk management.

Smart factories also offer a high level of automation: Intelligent systems that are part of a flexible network can automatically monitor production processes and respond in near real-time conditions, allowing for extensive optimization of internal production processes. Smart factory production brings several advantages over traditional manufacturing. These include: Efficient production processes: Smart factory systems are able to identify and identify required activities, configuration options and production conditions, and communicate independently with other units over a wireless network

Industry 4.0 is helping to create an intelligent network of independent machines that act as a bridge between the real world and the virtual world, representing key new aspects of the manufacturing and production processes. By connecting production technologies and intelligent manufacturing processes, Industry 4.0 is paving the way for the Internet of Things era, which will fundamentally change the manufacturing value chain and business model in the next few years.