Guide: If you ask China what application technology is leading the world? I will not hesitate to answer: aluminum industry technology! This conclusion is really not "Wang Po sell melon", it has an irrefutable factual basis. In the past 40 years of reform and opening up, China's aluminum industry is truly worthy of exaggerating achievements. It is not that production capacity accounts for more than half of the world's production, but that technological progress is leading the world.

From the upper, middle and lower reaches of the industrial chain, alumina, electrolytic aluminum, and aluminum processing, each of which has the top technology in the world.

First look at alumina production technology. China's independent research and development of low-grade bauxite ore to obtain alumina technology is enough to make the world "high mountain". There is a landmark indicator for measuring the grade of bauxite, called the ratio of aluminum to silicon. A simple understanding is the ratio of aluminum to silicon in the ore. The high bauxite ratio of aluminum to silicon means that the amount of aluminum is large and the alumina production efficiency is high. The World Aluminum Association has an aluminum to silicon ratio equal to 7 as a critical point, and an aluminum to silicon ratio of less than 7, such a bauxite is considered to be a waste mine with no economic exploitation value. However, Chinese aluminum industry technicians have developed a technology to efficiently produce alumina using low-grade bauxite with a ratio of aluminum to silicon of less than 7, and the use of low-grade ore has continued to expand from aluminum to silicon. Five, five, four, four, three, the current level, aluminum-silicon ratio of less than 3 bauxite can also be used in the production of alumina, this technology is far ahead of the world. This application technology is leading the world, not only has significant technical and economic significance, but also has a significant significance in greatly improving the utilization of the earth's resources and the service life of the mine. From the perspective of the history of human development, this is the Chinese aluminum industry's Great contribution. China is able to support 56% of the world's alumina production with less than 3% of the world's bauxite reserves, and low-grade bauxite applications are highly successful. Although some people say that domestic aluminum-silicon is less than 7 ore, research and development of low-grade bauxite utilization technology is a helpless situation of resource status, but technology leadership is leading. This is a fact, not active research or development. R & D to judge and define, the hero does not ask the source, success or failure only recognize the result.

Look at the electrolytic aluminum production technology. Taking the development and application of extra-large current electrolyzer technology as an example, it can reflect the advanced nature of China's electrolytic aluminum technology. In 1979, at the beginning of the reform and opening up, Guizhou Aluminum Plant introduced a complete set of 80,000 tons of 160 kA intermediate pre-baked electrolytic cell from Japan. Taking this as a starting point, China's electrolytic aluminum prebake cell technology has carried out innovative research and development on the basis of absorption and digestion, and has made major breakthroughs.

In the 1990s, the 280-kilometer large-scale prebaked electrolytic cell technology developed by Zhengzhou Research Institute won the first prize of National Science and Technology Progress Award. The 320-kilometer electrolyzer technology jointly developed by Pingguo Aluminum and Guiyang Aluminum-Magnesium Design Institute is the symbol of India, and China Aluminum Industry has achieved a historic leap from technology importing countries to technology exporting countries. In the 21st century, China's large-scale prebaked electrolytic cell technology continued to advance by leaps and bounds, and successively captured the three major barriers of 400,000, 500, and 600 thousand. In the same period, comparable to the advancement of electrolyzer technology, only China's high-speed rail technology, it has also overcome the three speeds of 200 km / h, 300 km / h and 400 km / h. However, the technological progress of China's aluminum industry is different from the nature of China's high-speed rail technology. China's high-speed rail technology is not alone. In the same period, the speed of high-speed rail in Germany and Japan is comparable to that of China's high-speed rail; while China's large-scale pre-bake cell technology The world's counterparts have long been left behind. When China's 600-kilometer cell technology has been put into production, only 350 kilowatts of electrolytic cell technology is operating abroad. China's electrolytic aluminum technology is as far ahead of the world as alumina technology.

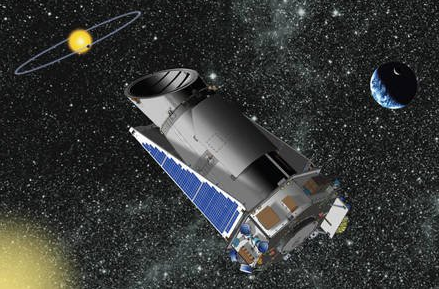

Look at the aluminum processing technology. The world's largest aluminum alloy rocket forging rings of 9 meters in diameter and 10 meters in diameter are made in China. This kind of aluminum processing technology is in the leading position in the world. Another world's first "China Eye", with a diameter of 500 meters, its reflective surface is a curved aluminum alloy material. Because of its huge curved surface, it has factors such as gravity, geomagnetic force, seasonal change, sun and rain, and other factors. Under the joint action, it is easy to cause parameter changes, and the technical requirements for material precision, smoothness, curvature, deflection, etc. are particularly high. The technical difficulty of developing such curved aluminum alloy materials is particularly difficult, and it is the roadblock of Yokohama on the road of "Tianyan" construction. . China's aluminum processing technicians have overcome many difficulties and successfully completed the development of aluminum alloy curved reflective materials. Since the establishment of the world's largest radio telescope, new celestial bodies have been discovered in distant universes, and the mysterious pulse signals from suspected foreign civilizations have been constantly received, which shocked the world. In the 2017 and 2018 New Year's Day speeches, General Secretary Xi Jinping cited 15 major scientific and technological achievements in 7 and 8 respectively, 12 of which contributed to the aluminum industry; General Secretary Xi Jinping at the party's 19th National Congress report The six national weapons, such as Tiangong, Xiaolong, Tianyan, Wukong, Mozi, and large aircraft, are equipped with domestic aluminum processing materials, which fully demonstrates that China's aluminum processing technology has entered the world's advanced ranks in the field of high-end new materials. In addition to major scientific and technological projects, China's aluminum industry also provides nearly 40 million tons of aluminum processing materials for all sectors of the national economy, accounting for more than 50% of the total global aluminum processing materials. China's aluminum processing technology meets China's Economic construction provides advanced technology to support and guarantee the demand for aluminum.

Of course, compared with the world's leading level, China's aluminum industry technology is still relatively backward in certain items, such as intelligent technology, 3D printing technology, high-end aluminum processing technology, etc., especially some high-end aluminum alloy materials are still dependent on imports, but from On the whole, the technological progress of China's aluminum industry in the past 40 years of reform and opening up has been advancing by leaps and bounds and is proud of.